After a week or two distracted by the OLED graphic display - which turned out to be damaged in the end - I've refocused on the core logger component.

I'm now using a simple LED which changes state every time a new line is written to the log buffer. Currently this occurs at slightly less than 0.5 second intervals so it's very obvious when logging stops.

The "refocusing" has meant I've found and squashed a couple of bugs that were causing intermittent issues with the log files. I've also discovered that the road speed data from the ECU is intermittently transmitted with an incorrect checksum. Until I found this issue I had assumed that I was logging too fast. Now that I've added handling for incorrect checksums the diagnostic connection will keep running after "ignition off" until the ECU shuts down.

With a bunch of bugs fixed the logger had a short road test this afternoon. In previous tests the connection would drop after 3 minutes maximum. This time around I was able to take the D2 for a 15 minute drive including a short run on a nearby freeway without out a hitch. I did have a moment of fuel cut as I accelerated on to the freeway and the logs show clearly the MAF sensor voltage climbing above the 4950mV upper limit, and the MAF reading dropping to 0.

A second run to work, to pick up a few things gave another opportunity to test the stability of the logger. The round trip was just under 30 minutes and I found I was able turn the motor off, switch back to accessory position, grab the things I needed from the office, then restart the engine and drive home without dropping the connection. The Nanocom is lucky to do the trip one way without throwing in the towel.

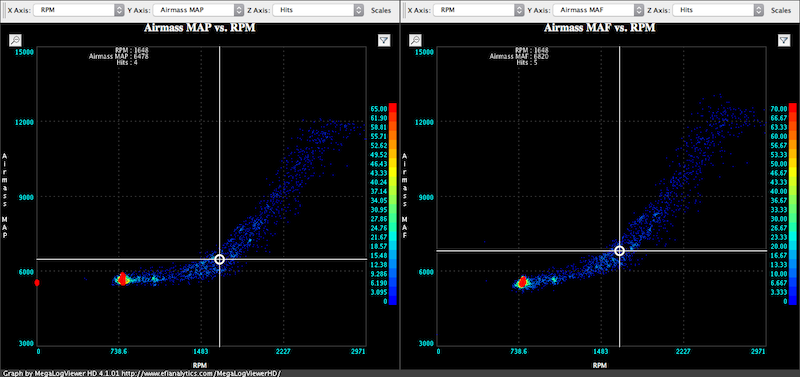

This is a quick comparison of the "Airmass per cycle" figures the ECU calculates from the MAF and MAP done using the MegaLog Viewer scatter plot function.